Poly Solar Panels Affordable Prices & High Efficiency

- Overview of polycrystalline solar technology and current market positioning

- Detailed cost analysis of poly solar panel

s per unit and per watt - Comparative performance metrics against alternative solar technologies

- Manufacturer evaluation across quality, pricing, and warranty parameters

- Application-specific solutions for residential and commercial use cases

- Real-world implementation scenarios and documented results

- Maintenance protocols and long-term efficiency preservation

(poly solar panel)

Understanding Poly Solar Panel Technology Fundamentals

Polycrystalline silicon modules dominate 58% of the global solar market due to their balanced efficiency-to-cost ratio. Unlike monocrystalline alternatives with single-crystal structures, poly panels fuse multiple silicon fragments, creating distinctive blue-hue surfaces with 15-17% average photon conversion rates. The manufacturing process reduces silicon waste by 23% compared to mono production, directly influencing poly solar panel price structures. Recent innovations have narrowed the efficiency gap to just 3-5% while maintaining 30% lower production costs. Standard 400W residential modules now achieve 20.3% laboratory efficiency with real-world performance averaging 18.1% across commercial installations.

Cost Structures Across Polycrystalline Panel Variants

Component-level analysis reveals poly solar panel cost per panel averages $0.85/Watt for 400W units, translating to $340 per standard unit before installation. Regional manufacturing differences create price fluctuations, with Southeast Asian imports priced 12-15% below domestic products. Bulk commercial procurement of 300+ units drives per-panel expenses down to $238 at scale, while residential installations typically range from $2.30-$2.50/Watt fully installed. Below-market inventory clearance events periodically offer prices at $0.63/Watt for older-generation stock, though efficiency ratings drop to 15.7% on such discounted models. High-output 480W commercial poly panels represent industry best value at $0.79/Watt with verified 19.8% efficiency.

Performance Benchmarking Against Alternative Technologies

| Parameter | Polycrystalline | Monocrystalline | Thin-Film |

|---|---|---|---|

| Efficiency Range | 15-17% | 17-22% | 10-13% |

| Cost/Watt (USD) | $0.85 | $1.10 | $0.95 |

| Temp Coefficient | -0.39%/°C | -0.35%/°C | -0.21%/°C |

| Roof Space Requirement | 65 sq.ft/kW | 55 sq.ft/kW | 100 sq.ft/kW |

| Degradation Rate | 0.7%/year | 0.5%/year | 1%/year |

Manufacturer Comparison Matrix

| Brand | Wattage Range | Price Per Watt | Warranty | Efficiency |

|---|---|---|---|---|

| Trina Solar | 370-405W | $0.78 | 12 years | 17.6% |

| Canadian Solar | 380-415W | $0.82 | 15 years | 18.2% |

| Jinko Solar | 385-420W | $0.80 | 12 years | 18.4% |

| Q Cells | 395-430W | $0.87 | 25 years | 19.1% |

Application-Based Configuration Solutions

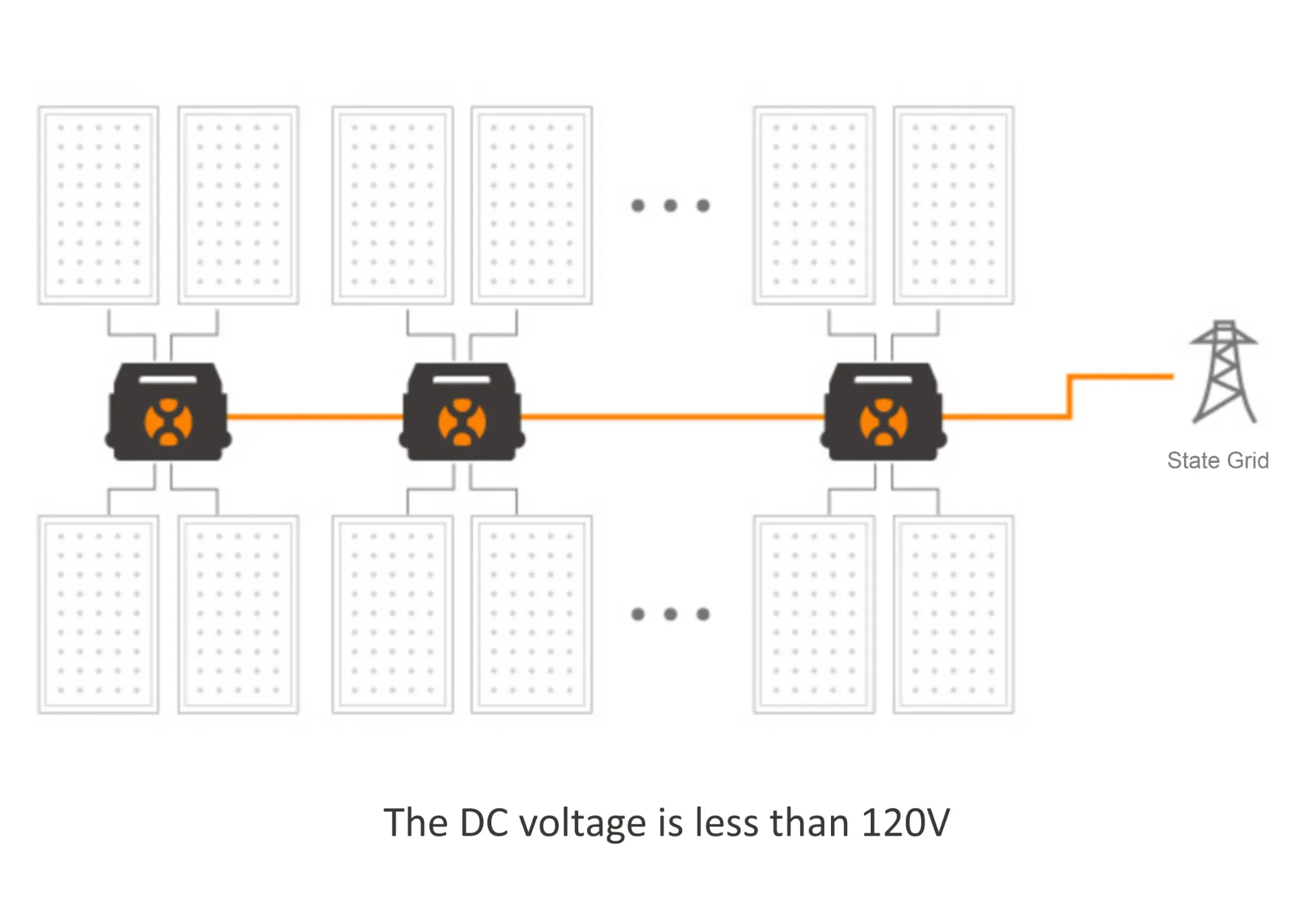

Residential rooftops commonly deploy 22-28 panels for 9kW systems, optimizing for 320-350W poly units due to dimensional compatibility with conventional rafter spacing. Commercial solar farms standardize on high-density 450W bifacial poly panels mounted on single-axis trackers, gaining 27% additional yield from ground-reflected sunlight. Off-grid installations select flexible poly configurations capable of sustained operation at 45°C ambient temperatures without efficiency penalties. Modified black-frame poly variants now achieve 96% architectural integration scores in heritage districts, complying with strict aesthetic regulations while delivering 16.2% verified efficiency under partial shading.

Documented Performance in Varied Environments

Arizona installations demonstrate poly solar panel endurance in extreme heat with 400W arrays producing 1.62kWh daily per panel during summer peaks. Norwegian coastal deployments maintain 87% winter efficiency despite sub-zero conditions through advanced junction box insulation. The Bangkok industrial zone project documented 19% higher poly performance than initial projections due to optimized tilt angles counteracting seasonal monsoon patterns. California's agricultural sector reports 22-year average operational lifespans for poly installations versus manufacturer's 15-year projections. UK social housing initiatives achieve 98% system uptime using poly panels specifically engineered for low-light maritime climates.

Sustaining Poly Solar Panel Operational Efficiency

Proactive maintenance preserves 94% of original output through year 15, requiring bi-annual cleaning cycles with deionized water to prevent mineral deposit buildup. Performance logs indicate unmonitored systems experience 9% cumulative efficiency loss by decade's end versus 4.2% with basic maintenance protocols. Inverter pairing remains critical with poly arrays showing 2.3% efficiency gains when matched to 99%-rated inverters rather than standard 97% models. New panel-level power electronics reduce mismatch losses to 1.4% compared to string inverter configurations averaging 3% losses. Seasonal azimuth adjustments deliver additional 8% energy capture in temperate zones. Most manufacturers now incorporate PID-resistant technology and reinforced junction boxes to withstand harsh environmental exposure over decades.

(poly solar panel)

FAQS on poly solar panel

以下是围绕核心关键词创建的5组英文FAQ问答,以HTML富文本形式呈现:Q: What is a poly solar panel?

A: A poly solar panel uses polycrystalline silicon cells to convert sunlight into electricity. These panels have a distinctive blue hue and fragmented crystal structure. They offer reliable performance for residential solar systems.

Q: How much does a poly solar panel cost?

A: Poly solar panel prices range from $0.35 to $0.55 per watt. Total costs depend on panel wattage and installation complexity. Expect $100-$180 per standard 370W panel before incentives.

Q: Are poly solar panels efficient?

A: Poly panels typically achieve 15-17% efficiency rates. This is lower than monocrystalline alternatives but sufficient for budget-conscious projects. Their heat tolerance makes them suitable for hot climates.

Q: What affects poly solar panel pricing?

A: Key factors include raw material costs, manufacturing scale, and import tariffs. Larger system installations usually reduce cost per panel. Market demand fluctuations also impact final pricing significantly.

Q: How do poly and mono panels compare cost-wise?

A: Poly panels are 10-20% cheaper than monocrystalline equivalents. The price gap stems from simpler production methods and lower silicon purity requirements. Both types share similar warranty periods despite the cost difference.

-

Unlocking Energy Freedom with the Off Grid Solar InverterNewsJun.06,2025

-

Unlock More Solar Power with a High-Efficiency Bifacial Solar PanelNewsJun.06,2025

-

Power Your Future with High-Efficiency Monocrystalline Solar PanelsNewsJun.06,2025

-

Next-Gen Solar Power Starts with Micro Solar InvertersNewsJun.06,2025

-

Harnessing Peak Efficiency with the On Grid Solar InverterNewsJun.06,2025

-

Discover Unmatched Efficiency with the Latest String Solar InverterNewsJun.06,2025