solar panels how they are made

How Solar Panels Are Made A Comprehensive Overview

In an era where renewable energy is becoming increasingly vital for sustainable development, solar panels have emerged as one of the most effective tools for harnessing solar energy. Understanding how solar panels are made not only helps in appreciating their technology but also illuminates the processes that contribute to clean energy. This article explores the intricate manufacturing process of solar panels, highlighting the materials, steps involved, and the innovations transforming this industry.

Raw Materials

The manufacturing of solar panels begins with raw materials, primarily silicon. Silicon is a versatile and abundant natural element found in sand and quartz. It is the fundamental building block of most solar panels due to its excellent semiconductor properties. Other key materials used in solar panel production include glass, ethylene vinyl acetate (EVA), backsheet materials, and various metals such as aluminum for the frame and conductive materials for electrical connections.

Silicon Production

The journey of solar panels starts with silicon extraction. Sand is purified to produce metallurgical-grade silicon, which is then further refined to create polysilicon. This high-purity silicon is essential for the photovoltaic cells that convert sunlight into electricity. The production of polysilicon is energy-intensive, involving processes such as reacting silicon with hydrochloric acid and subsequently refining it through a chemical vapor deposition method.

Wafer Production

Once polysilicon is produced, it is melted and formed into cylindrical ingots. These ingots are then sliced into thin wafers using diamond wire saws. The thickness of these wafers is critical as it influences the efficiency and performance of the solar cells. Typically, wafers range from 180 to 200 micrometers thick. After slicing, the wafers undergo cleaning and polishing to remove any residues and imperfections.

Cell Fabrication

The next phase in the solar panel manufacturing process is the creation of solar cells. Wafers are treated to create a p-n junction, which is essential for generating an electric field. This is accomplished through the diffusion of phosphorus or boron onto the surface of the wafers to create a positive (p-type) and negative (n-type) layer. Afterward, the cells are subjected to anti-reflective coating to minimize sunlight reflection and maximize absorption.

solar panels how they are made

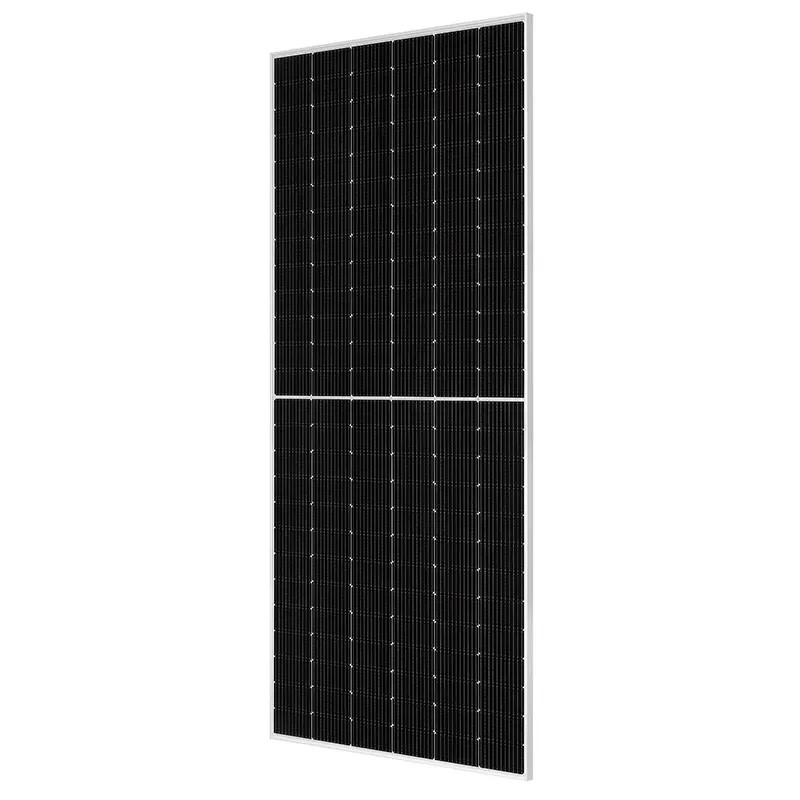

Assembling Solar Modules

Once the solar cells are fabricated, they are assembled into solar modules. This involves connecting multiple cells in a series or parallel arrangement to increase voltage and current output. The interconnected cells are then encapsulated in layers of EVA and glass to protect them from environmental damage. This encapsulation process is critical for ensuring the longevity and efficiency of solar panels.

After encapsulation, the modules are placed in an oven to be laminated, which fuses the layers together, creating a robust and weatherproof panel. Following lamination, the backsheet is added, providing an extra layer of protection against moisture and mechanical stress.

Testing and Quality Control

Quality assurance is paramount in solar panel production. The finished modules undergo rigorous testing to ensure they meet industry standards. Tests typically assess electrical performance, thermal cycling, humidity, and mechanical robustness. Panels are often exposed to simulated environmental conditions to assess their durability and reliability over time.

Innovations and Future Trends

The solar panel industry is continually evolving, with innovations enhancing efficiency and sustainability. Recent advancements include the development of bifacial solar panels, which can capture sunlight from both sides, significantly increasing energy output. Additionally, researchers are exploring alternative materials, such as perovskite solar cells, which promise higher efficiency at lower costs.

Conclusion

The making of solar panels is a complex interplay of materials, processes, and technology. From the extraction of raw silicon to the assembly of solar modules, each step is crucial in producing efficient solar panels that harness the sun's energy. As innovations drive the industry forward, solar panels remain a cornerstone of the transition towards renewable energy, promising a sustainable future for generations to come. Understanding this manufacturing journey not only highlights the intricacies of solar technology but also emphasizes the importance of investing in clean energy solutions.

-

Unlocking Energy Freedom with the Off Grid Solar InverterNewsJun.06,2025

-

Unlock More Solar Power with a High-Efficiency Bifacial Solar PanelNewsJun.06,2025

-

Power Your Future with High-Efficiency Monocrystalline Solar PanelsNewsJun.06,2025

-

Next-Gen Solar Power Starts with Micro Solar InvertersNewsJun.06,2025

-

Harnessing Peak Efficiency with the On Grid Solar InverterNewsJun.06,2025

-

Discover Unmatched Efficiency with the Latest String Solar InverterNewsJun.06,2025