Cost Analysis of Factory-Made Solar Panels for Efficient Energy Solutions

The Cost of Factory Solar Panels A Comprehensive Overview

The shift towards sustainable energy sources has prompted many industries to explore alternatives to traditional electricity generation methods. Among these alternatives, solar energy stands out as one of the most promising. The use of solar panels, particularly factory-produced ones, offers a viable solution for businesses looking to reduce their carbon footprint and energy costs. However, understanding the cost associated with factory solar panels is crucial for businesses planning to implement solar energy solutions.

What Are Factory Solar Panels?

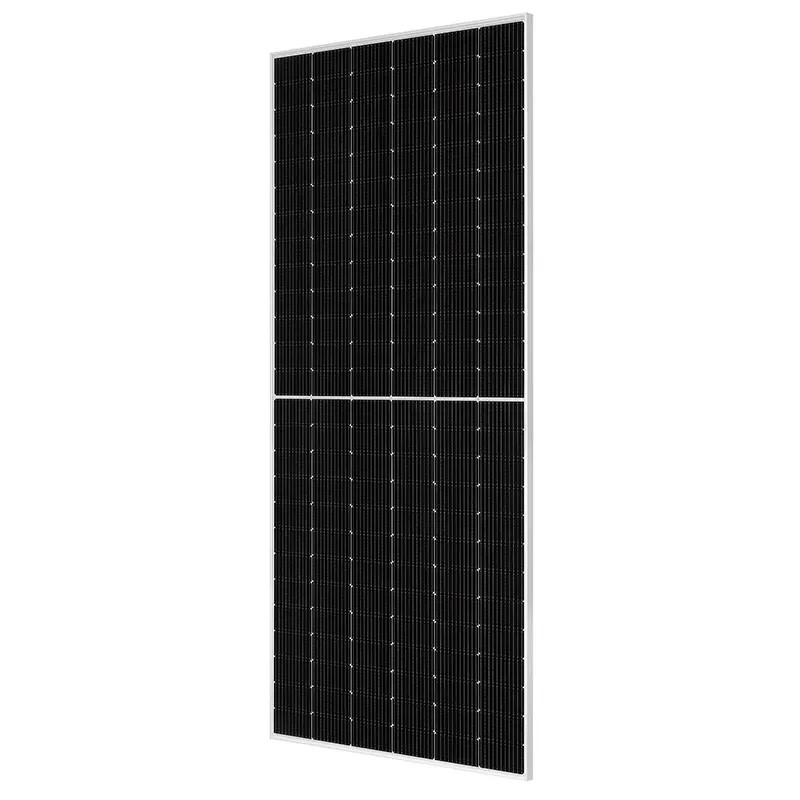

Factory solar panels, also known as manufactured or commercial solar panels, are produced in large-scale facilities with specialized machinery and technology. These panels are designed for efficiency and durability, allowing them to generate electricity even under less-than-ideal conditions. Manufacturing solar panels on a large scale helps in reducing production costs while also meeting the demands of the growing solar market.

Factors Influencing the Cost of Factory Solar Panels

The cost of factory solar panels is influenced by several interrelated factors

1. Material Composition The primary materials used in the manufacturing of solar panels include silicon, glass, and metals. The price of these raw materials can fluctuate based on market demand and supply chain dynamics. For instance, silicon prices have risen and fallen in recent years, significantly impacting the overall cost of solar panels.

2. Manufacturing Processes Different manufacturing processes can lead to variations in costs. Advanced technology and automation in production lines can improve efficiency and reduce labor costs, allowing manufacturers to offer competitive prices. However, the initial investment in sophisticated machinery can be substantial.

3. Scale of Production Economies of scale play a vital role in determining the cost of factory solar panels. Manufacturers that produce panels in large quantities can spread their fixed costs over a larger volume, thus lowering the per-unit price. This trend has been observed in recent years as the solar industry continues to expand.

4. Technological Advancements Innovation in solar technology can also affect costs. New methods for increasing panel efficiency or reducing material usage can lead to lower production costs. For instance, the emergence of bifacial solar panels, which can capture sunlight from both sides, has created new opportunities for reducing costs while enhancing energy output.

factory solar panels cost

5. Geographical Location The location of the manufacturing facility can also impact the cost. Regions with lower wages may have cheaper production costs, but there may be other factors such as transportation expenses and regulatory costs that can offset these savings. Additionally, local incentives or tariffs can influence pricing.

6. Market Demand and Competition The demand for solar panels has surged in recent years, driven by a global push for renewable energy. High demand often leads to increased prices; however, an influx of new manufacturers can foster competition, leading to more competitive pricing.

The Cost of Installation

While the cost of factory solar panels is significant, it is essential to consider installation costs, which can also vary widely. Installation costs depend on several factors, including

- Site Assessment and Preparation Before installation, a thorough assessment of the site must be conducted, and preparation may require modifications to existing structures.

- Labor Costs Hiring qualified technicians for the installation process can add to the overall expense. The complexity of the installation and regional labor rates will influence this cost.

- Permitting and Inspections Navigating local regulations to obtain necessary permits can lead to additional costs. Many regions require inspections to ensure compliance with safety and building codes.

Conclusion

The cost of factory solar panels involves various factors ranging from production materials to installation complexities. Businesses looking to invest in solar energy must conduct comprehensive cost analyses to determine the feasibility of this investment. Despite the initial costs, solar energy presents long-term savings and environmental benefits, making it a compelling option for many industries. With technological advancements and increased competition in the solar market, it is likely that the costs of factory solar panels will continue to evolve, making this renewable energy source more accessible to a broader range of businesses and consumers. Transitioning to solar energy is not just an investment in the future; it is also a step towards a more sustainable planet.

-

Understanding the Advantages of Solar String Inverters for Your Energy SystemNewsApr.29,2025

-

Choosing the Right PV Inverter: A Comprehensive GuideNewsApr.29,2025

-

The Future of Solar Power: Exploring Bifacial Solar PanelsNewsApr.29,2025

-

The Complete Guide to Solar Panels: Efficiency, Cost, And InstallationNewsApr.29,2025

-

The Best Options for Efficiency and Cost-EffectivenessNewsApr.29,2025

-

Harnessing the Power of Off-Grid Solar Inverters for Energy IndependenceNewsApr.29,2025