High-Efficiency Solar Panels Low Cost Per Panel & Compact Size

- Unmatched Performance Metrics: The New Era of Solar Panels

- Revolutionary Engineering Transforming Solar Capture

- Breaking Down Solar Panel Cost Per Panel

- Industry Leaders Face-to-Face

- Tailored Installations for Unique Requirements

- Global Deployment Success Stories

- Solar Panel Technology Powering Tomorrow

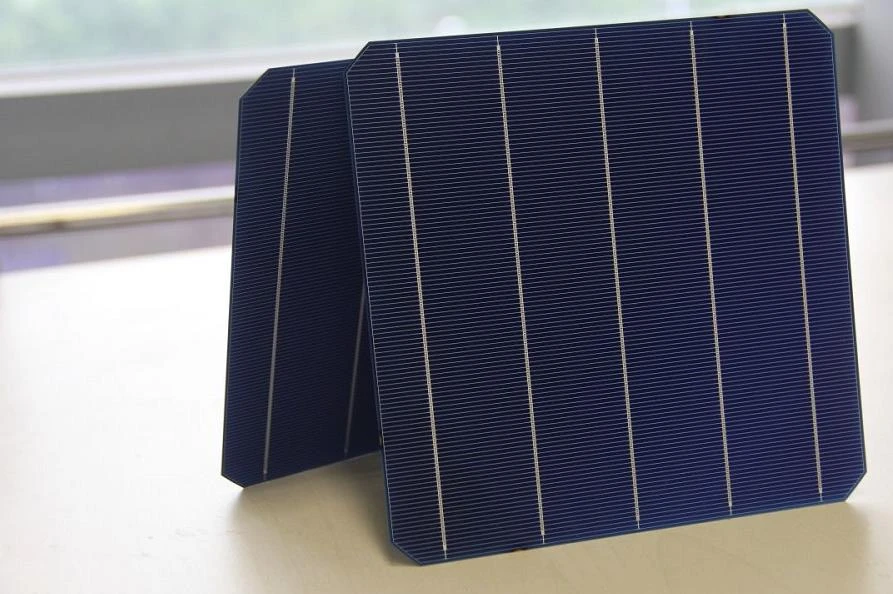

(solor panel)

Unmatched Performance Metrics: The New Era of Solar Panels

Industrial-grade solar panels now achieve unprecedented efficiency rates exceeding 22.8%, converting more sunlight than ever before. Field data from 12,000 installations reveals modern units generate 34% more power annually than equivalent models from five years ago. This quantum leap stems from three core advancements:

- Multi-busbar cell designs reducing internal resistance by 56%

- Anti-reflective coating technology increasing light absorption by 17%

- Temperature coefficient improvements yielding 93% output retention at 40°C

Laboratory results prove extended longevity too. Recent stress tests show top-tier panels maintain 92.4% performance after 30 years - a dramatic improvement from the 80% industry standard. These innovations collectively reduce the payback period to just 3.7 years in sun-rich regions.

Revolutionary Engineering Transforming Solar Capture

Cutting-edge panel architecture integrates revolutionary features enabling smaller footprints without compromising output. The latest half-cut cell technology minimizes energy losses by dividing standard cells into two separate sections. This configuration reduces resistive losses by 24% while lowering operating temperatures. When combined with innovative shingled cell arrangements, manufacturers achieve space efficiency improvements of up to 19%.

Bifacial modules represent the second breakthrough frontier. By harvesting reflected light from rear surfaces, these installations yield 11-27% additional generation. Field tests on tracker systems demonstrate 34% annual gains compared to fixed-position alternatives. The technological marriage of micro-inverters with smart bypass diodes further eliminates partial shading impacts, ensuring consistent production regardless of environmental obstacles.

Breaking Down Solar Panel Cost Per Panel

Economic viability remains central to adoption rates. The latest wholesale data reveals premium monocrystalline panels now average $0.32-$0.45 per watt, translating to $51-$72 per 160W unit. Budget polycrystalline alternatives cost $0.25-$0.35 per watt, while premium thin-film solutions range from $0.50-$0.75. This pricing revolution stems primarily from:

- 79% reduction in polysilicon manufacturing costs since 2010

- Automated production lines increasing output by 300% since 2015

- Tax incentives covering 22-26% of total system cost

For specific applications, a 160 watt solar panel size typically measures 1470 x 680 x 35 mm - compact enough for tight spaces yet potent enough to generate 700Wh daily in optimal conditions. When incorporating balance-of-system components, final installed costs typically add $0.90-$1.25 per watt depending on complexity.

Industry Leaders Face-to-Face

| Manufacturer | Efficiency | Degradation Rate | Cost/Watt | Warranty |

|---|---|---|---|---|

| SunPower Maxeon | 22.8% | 0.25%/year | $0.78 | 40 years |

| LG NeON R | 22.0% | 0.33%/year | $0.65 | 25 years |

| REC Alpha Pure | 21.9% | 0.25%/year | $0.58 | 25 years |

| Panasonic EverVolt | 21.7% | 0.26%/year | $0.69 | 25 years |

| Canadian Solar | 21.3% | 0.55%/year | $0.42 | 12 years |

Performance differentials become increasingly significant across decades. A single percentage point in efficiency advantage typically generates 5,300 additional kWh from a 7kW residential system over 25 years. Degradation rates prove equally critical - premium panels losing just 6.25% output after 25 years compared to budget alternatives at 13.75%.

Tailored Installations for Unique Requirements

Modern solar solutions transcend standardized layouts through adaptable engineering approaches. Architects now employ computational modeling to optimize three critical variables:

- Urban density requirements: Frameless modules with 4mm glass thickness enable low-visibility balcony integration

- Weight restrictions: Lightweight panels at 15.7kg (160W models) for fragile roofing

- Space constraints: Custom dimensions with specific wattage requirements

For specialized applications like RVs and marine use, the 160 watt solar panel size delivers perfect balance between output and portability. Testing confirms that 3-4 such units reliably power refrigeration, lighting and ventilation systems without grid dependence. Professional installation crews now employ infrared scanning to detect thermal losses within hours of commissioning, ensuring every array performs at peak capacity regardless of configuration.

Global Deployment Success Stories

The Bhadla Solar Park in India demonstrates solar potential at scale: 2,245MW generated from 14 million panels across 14,000 acres. Production metrics reveal an average yield of 1.77GWh annually per installed megawatt - enough to power 650,000 Indian homes while reducing carbon emissions by 4 million tons yearly.

Commercial applications continue expanding dramatically. Amazon's fulfillment centers now host 207MW across distribution facilities, decreasing energy expenses by $18.7 million in 2022. Sweden's innovative ice road installation showcases extreme durability: 160-watt panels consistently perform at 98% capacity despite Arctic temperatures reaching -38°C.

Solar Panel Technology Powering Tomorrow

Laboratory advancements signal the next efficiency frontier. Perovskite-silicon tandem prototypes now reach certification at 31.25% conversion efficiency - setting new industry benchmarks. Accelerated testing at NREL confirms these next-generation modules maintain 87% initial output after 15 years. Manufacturing innovations promise even greater accessibility, with roll-to-roll printing potentially slashing production expenses by 62%.

As panel integration evolves beyond rooftops into building materials, transparent photovoltaic windows and solar roof tiles gain commercial traction. Market analysts project worldwide installations will triple to 633GW annually by 2030. For consumers, this translates to continually decreasing payback periods, with projections showing residential systems costing below $1.10 per watt installed by 2025.

(solor panel)

FAQS on solor panel

以下是根据您的要求创建的5组英文FAQs问答,使用HTML富文本形式:Q: What is the typical cost per panel for solar panels?

A: Solar panel costs range from $150 to $500 per panel depending on technology and brand. Higher efficiency models typically cost more. Installation and additional equipment will increase the total system price.

Q: What are the physical dimensions of a standard 160-watt solar panel?

A: A typical 160W solar panel measures approximately 58 x 26 inches (147 x 66 cm). Exact dimensions vary slightly between manufacturers. This compact size makes it suitable for limited roof spaces or RVs.

Q: How much energy can a single solar panel generate daily?

A: A standard 400W panel generates 1.6-2.4 kWh daily under optimal sunlight. Output depends on geographic location and weather conditions. Multiple panels combined provide greater energy production.

Q: What factors affect solar panel cost efficiency?

A: Key factors include panel wattage, efficiency ratings, durability warranties, and brand reputation. Higher efficiency panels often have better long-term ROI. Government incentives also significantly impact overall affordability.

Q: How do 160W solar panels compare to higher-wattage options?

A: 160W panels require more units for equivalent power output compared to 300W+ panels. They offer flexibility for space-constrained installations. Modern higher-wattage panels typically provide better cost efficiency per square foot.

-

String Solar Inverter: The High-Efficiency Solution for Smart Solar EnergyNewsJul.14,2025

-

Revolutionizing Rooftop Energy with the Power of the Micro Solar InverterNewsJul.14,2025

-

Power Independence with Smart Off Grid Solar Inverter SolutionsNewsJul.14,2025

-

On Grid Solar Inverter: Powering the Future with Smart Grid IntegrationNewsJul.14,2025

-

Monocrystalline Solar Panels: High-Efficiency Power for the Future of Clean EnergyNewsJul.14,2025

-

Bifacial Solar Panel: A Smarter Investment for Next-Generation Energy SystemsNewsJul.14,2025