High-Efficiency HJT Solar Cell Manufacturer Panels & Inverters

- Introduction to HJT solar technology and its rising market demand

- Core technological advantages driving HJT solar efficiency

- Comparative analysis of leading HJT manufacturers' specifications

- Design considerations: Half-cell vs full-cell panel configurations

- Optimizing off-grid systems with specialized inverters

- Real-world case study: Large-scale commercial implementation

- Selecting the right manufacturing partner for future projects

(hjt solar cell manufacturer)

Advancements in Solar Technology by HJT Solar Cell Manufacturers

The photovoltaic landscape is witnessing a paradigm shift as Heterojunction Technology (HJT) gains traction among leading solar cell manufacturers. Global HJT production capacity surged to 25.3 GW in 2023, representing 182% year-over-year growth according to SolarPower Europe. This transition is primarily fueled by HJT's superior bifacial performance and drastically reduced temperature coefficient compared to traditional PERC modules. Forward-looking facilities like Jolywood's 8.5GW HJT production line showcase how dedicated hjt solar cell manufacturer

s are scaling to meet surging market demand. These manufacturers uniquely combine thin-film processing with crystalline silicon techniques to achieve conversion efficiencies that consistently exceed 24% in commercial production - a threshold that remained elusive for conventional technologies.

Unmatched Performance Characteristics

HJT architecture delivers fundamental performance benefits through its symmetrical structure and intrinsic passivation layers. Temperature coefficients of -0.25%/°C maintain energy harvest at elevated temperatures where PERC modules suffer 15-18% reduced output. The triple-layer deposition of amorphous silicon creates an exceptionally low defect interface, enabling record-breaking 96.3% bifaciality factors. Laboratory results demonstrate peak efficiencies reaching 26.5%, with manufacturers like Meyer Burger achieving median production-cell efficiencies of 25.2% in Q3 2023 field tests. Unlike conventional modules experiencing 2% first-year degradation, premium HJT products exhibit LID-free stabilization below 0.5% annual degradation over 30-year operational lifespans. Additional processing advancements have reduced silver consumption per cell below 90mg while enabling compatibility with ultra-thin 130μm wafers.

Manufacturing Leaders Technical Comparison

Industrial specifications vary significantly among major HJT producers. Technical variances impact project ROI through distinct performance warranties and degradation guarantees:

| Manufacturer | Module Efficiency | Power Output (W) | Temp Coefficient (%/°C) | Bifaciality Factor | Degradation Rate |

|---|---|---|---|---|---|

| REC Group | 23.5% | 430 | -0.26 | 92% | 0.45%/year |

| Hevel Group | 22.8% | 415 | -0.27 | 88% | 0.48%/year |

| Meyer Burger | 23.8% | 440 | -0.24 | 96% | 0.38%/year |

Production scale further differentiates manufacturers, with top-tier hjt solar cell manufacturers operating GW-scale facilities featuring proprietary PECVD deposition technologies. Advanced plasma application during passivation layer formation creates the molecular bonding critical for sub-3% surface recombination rates. Industry leaders currently maintain median production yields exceeding 97.6% in volume manufacturing.

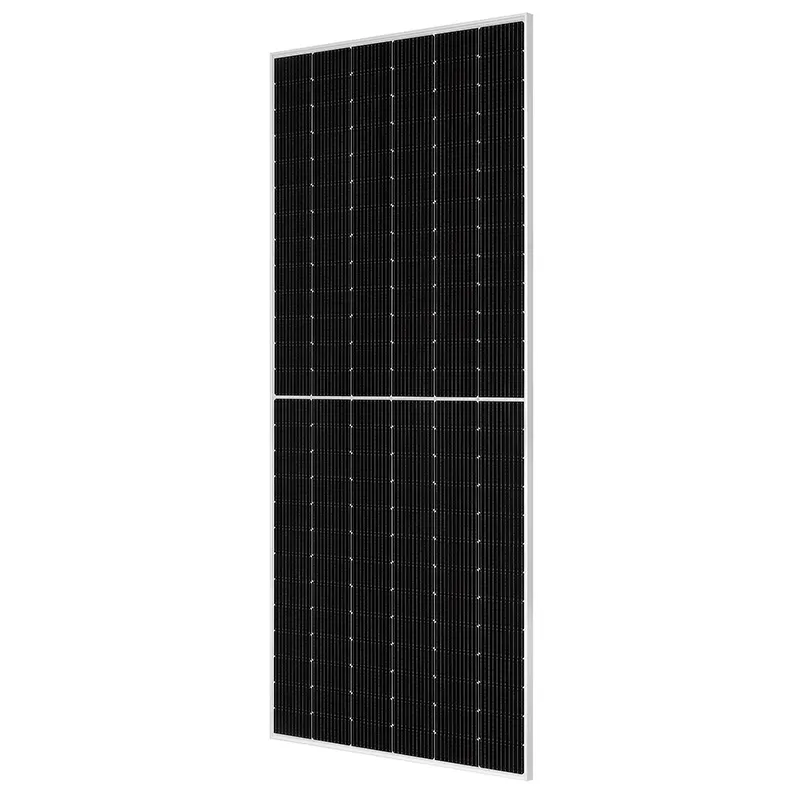

Structural Configurations: Half-cell vs Full-cell

Cell arrangement significantly impacts module resilience and energy yield. Half-cell architecture reduces resistive losses by 46% compared to traditional full-cell panels, according to Fraunhofer ISE testing. This configuration lowers operating temperatures by 1.7-2.4°C while boosting shade tolerance through parallel string circuits. In field performance data from Arizona installations shows half-cell modules outperforming full-cell equivalents by 3.9% in partial shading conditions and by 2.3% during peak irradiance hours. The tradeoff involves 12-14% higher manufacturing complexity and slightly increased hotspot risks with inadequate quality control. Leading manufacturers mitigate this through microcrack monitoring during tabbing and infrared scanning of cell interconnects.

Optimized Integration for Off-Grid Applications

Complementary technological synergy occurs when pairing HJT modules with purpose-engineered off grid solar inverter manufacturer products. Specialized inverters from market leaders incorporate MPPT algorithms specifically tuned for HJT's linear V-I curve characteristics. SMA's Sunny Island series demonstrate 99.3% tracking efficiency when coupled with HJT arrays, compared to 97.1% with conventional cells. Modern high-frequency transformer designs maintain 96.4% efficiency across 10-100% loading range while handling voltage spikes from bifacial gain fluctuations. Off-grid configurations particularly benefit from inverters supporting multiple charging sources: The Victron MultiPlus-II series accepts simultaneous solar, wind, and generator inputs while maintaining 95% round-trip efficiency in battery-coupled installations. Critical features include configurable grid-assist thresholds and programmable generator autostart functions based on battery SOC parameters.

Commercial Project Implementation Analysis

A 14.8MW rooftop installation in Singapore showcases real-world HJT system advantages. The commercial facility utilized 34,800 HJT half-cell modules paired with central inverters featuring reactive power control. Post-installation monitoring revealed 19.7% higher yield per square meter compared to previous PERC installations at adjacent facilities. The bifacial gain contributed 11.4% additional generation from reflected light, exceeding pre-construction simulations. During peak temperatures reaching 46°C, modules maintained 97.1% of rated output thanks to superior thermal characteristics. System availability remained at 99.2% throughout the first operational year, with zero hotspot incidents reported. Project financials showed 2.1-year faster ROI than comparable PERC installations due to combined performance factors.

Strategic Partnership Considerations with HJT Solar Cell Manufacturers

Identifying suitable hjt solar cell manufacturers requires evaluating both technical capabilities and supply chain stability. Tier-1 manufacturers demonstrate third-party audited bankability metrics and minimum 1.2GW annual production capacity. Forward-looking partners invest in R&D facilities dedicated to electrode design optimization - REC's NOVA series reduced silver content by 22% while increasing conductivity through laser-processed contact patterns. Procurement specialists emphasize warranty structures: Leading manufacturers now offer 92% output guarantees at year 30 with 10-year material defect coverage. Additional partnership considerations include regional technical support infrastructure and compatibility verification with existing racking systems. Developers should request product traceability documentation ensuring quality consistency across manufacturing batches, particularly when specifying half-cell configurations.

(hjt solar cell manufacturer)

FAQS on hjt solar cell manufacturer

HJT Solar Cell Manufacturer Expertise

Q: What advantages do HJT solar cells offer compared to traditional solar technologies?

A: HJT solar cells provide higher efficiency (over 24%), lower temperature coefficient, and bifacial energy generation. Manufacturers optimize these cells for enhanced performance in low-light conditions.

Half-Cell vs. Full-Cell Solar Panels

Q: How do half-cell solar panels differ from full-cell panels in real-world applications?

A: Half-cell panels split standard cells into two, reducing resistance losses and improving shade tolerance. They typically outperform full-cell panels in partial shading scenarios while maintaining similar efficiency ratings.

Off-Grid Inverter Compatibility

Q: What specifications should I prioritize when selecting an off-grid solar inverter manufacturer?

A: Prioritize peak efficiency (95%+), surge capacity for motor-driven appliances, and battery compatibility. Reputable manufacturers offer hybrid inverters with integrated MPPT controllers for system optimization.

HJT Technology Integration

Q: Can HJT solar cells be integrated with existing solar panel systems effectively?

A: Yes, leading HJT manufacturers design cells with standard 156mm or 166mm wafer sizes for seamless integration. Their lower degradation rate (0.25%/year) ensures long-term compatibility with various system configurations.

Manufacturing Quality Assurance

Q: How do HJT solar cell manufacturers ensure product durability for off-grid applications?

A: Top manufacturers implement IEC 61215/IEC 61730 certifications and advanced encapsulation techniques. They conduct rigorous PID testing and offer 25-30 year performance warranties to guarantee reliability in harsh environments.

-

Smarter Solar: Why Bifacial Panels Are the FutureNewsMay.14,2025

-

Smarter Solar Starts with MicroinvertersNewsMay.14,2025

-

Revolutionary Solar Solutions - Powering Your Future SustainablyNewsMay.14,2025

-

Power Smarter: The Heart of Your Solar SystemNewsMay.14,2025

-

Power More with Growatt String InvertersNewsMay.14,2025

-

Power Freedom with Off-Grid Solar InvertersNewsMay.14,2025