فبراير . 17, 2025 19:50

Back to list

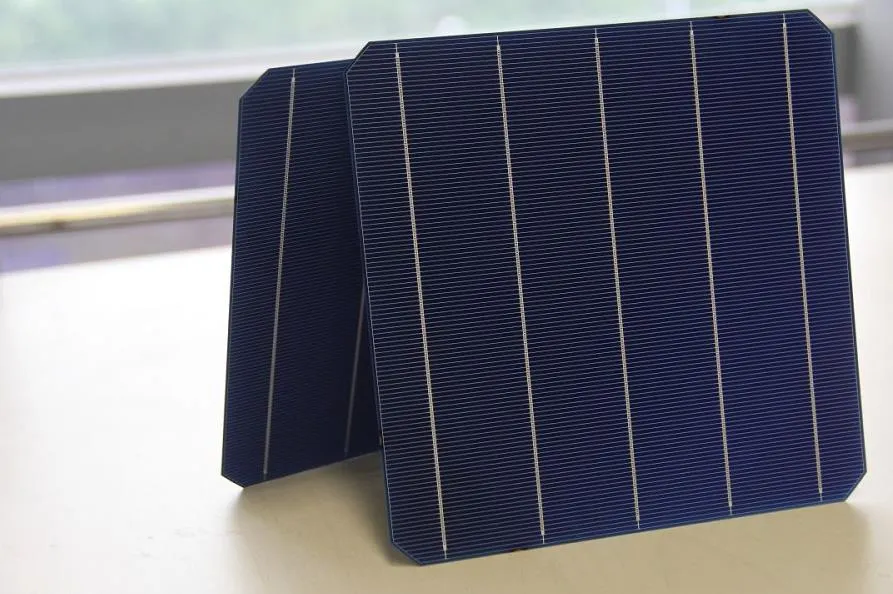

monocrystalline solar panel manufacturer

The decision to integrate solar energy solutions into a factory setting often hinges on several key considerations, with cost remaining a critical factor for any business. As more industries move towards sustainable energy sources, understanding the various cost implications of solar panel installation in a factory setting becomes essential. Here, we delve into the nuances of solar panel costs for factories, aligned with practical experiences, expert perspectives, and authoritative insights to guide businesses in making informed decisions.

Tax incentives, rebates, and funding options significantly impact the affordability of solar panels for factories. Governments worldwide are fostering the transition to renewable energy through various economic incentives. In the United States, for example, the Investment Tax Credit (ITC) offers a significant reduction in solar panel installation costs, allowing factories to deduct a substantial percentage of solar-related expenditures from their federal taxes. Additionally, some states offer accelerated depreciation benefits under the Modified Accelerated Cost Recovery System (MACRS), which can further enhance financial savings. Factories should engage with tax professionals or energy consultants familiar with local and federal policies to fully capitalize on these opportunities. Understanding the long-term economic benefits is equally important. Solar panels promise reduced electricity bills, providing a hedge against fluctuating energy prices. By generating their own electricity, factories can dramatically lower operational costs. Studies have shown that investing in solar can result in payback periods as short as 5 to 8 years, with a system lifespan that often extends 25 years or more. This makes solar energy a lucrative investment by not only lowering immediate energy expenditures but also stabilizing future operating budgets against rising utility rates. Moreover, there’s an environmental cost-saving element that is often overlooked. Consumers and partners increasingly favor businesses with sustainable practices. By powering operations with solar energy, factories can enhance their brand image and fulfill corporate social responsibility goals, which can translate into increased market appeal and potentially new business opportunities. In conclusion, the decision to adopt solar panels in a factory setting involves not just a financial analysis but also a strategic vision for sustainability and long-term investment. By considering both the upfront and ongoing costs, maximizing available incentives, and leveraging expertise in the field, factories can effectively transition to solar energy, unlocking both economic and environmental benefits. As the global market continues to evolve, forward-thinking businesses that prioritize these clean energy solutions position themselves at the forefront of industry innovation and operational efficiency.

Tax incentives, rebates, and funding options significantly impact the affordability of solar panels for factories. Governments worldwide are fostering the transition to renewable energy through various economic incentives. In the United States, for example, the Investment Tax Credit (ITC) offers a significant reduction in solar panel installation costs, allowing factories to deduct a substantial percentage of solar-related expenditures from their federal taxes. Additionally, some states offer accelerated depreciation benefits under the Modified Accelerated Cost Recovery System (MACRS), which can further enhance financial savings. Factories should engage with tax professionals or energy consultants familiar with local and federal policies to fully capitalize on these opportunities. Understanding the long-term economic benefits is equally important. Solar panels promise reduced electricity bills, providing a hedge against fluctuating energy prices. By generating their own electricity, factories can dramatically lower operational costs. Studies have shown that investing in solar can result in payback periods as short as 5 to 8 years, with a system lifespan that often extends 25 years or more. This makes solar energy a lucrative investment by not only lowering immediate energy expenditures but also stabilizing future operating budgets against rising utility rates. Moreover, there’s an environmental cost-saving element that is often overlooked. Consumers and partners increasingly favor businesses with sustainable practices. By powering operations with solar energy, factories can enhance their brand image and fulfill corporate social responsibility goals, which can translate into increased market appeal and potentially new business opportunities. In conclusion, the decision to adopt solar panels in a factory setting involves not just a financial analysis but also a strategic vision for sustainability and long-term investment. By considering both the upfront and ongoing costs, maximizing available incentives, and leveraging expertise in the field, factories can effectively transition to solar energy, unlocking both economic and environmental benefits. As the global market continues to evolve, forward-thinking businesses that prioritize these clean energy solutions position themselves at the forefront of industry innovation and operational efficiency.

Latest news

-

Unlocking Energy Freedom with the Off Grid Solar InverterNewsJun.06,2025

-

Unlock More Solar Power with a High-Efficiency Bifacial Solar PanelNewsJun.06,2025

-

Power Your Future with High-Efficiency Monocrystalline Solar PanelsNewsJun.06,2025

-

Next-Gen Solar Power Starts with Micro Solar InvertersNewsJun.06,2025

-

Harnessing Peak Efficiency with the On Grid Solar InverterNewsJun.06,2025

-

Discover Unmatched Efficiency with the Latest String Solar InverterNewsJun.06,2025

Related PRODUCTS