فبراير . 15, 2025 05:47

Back to list

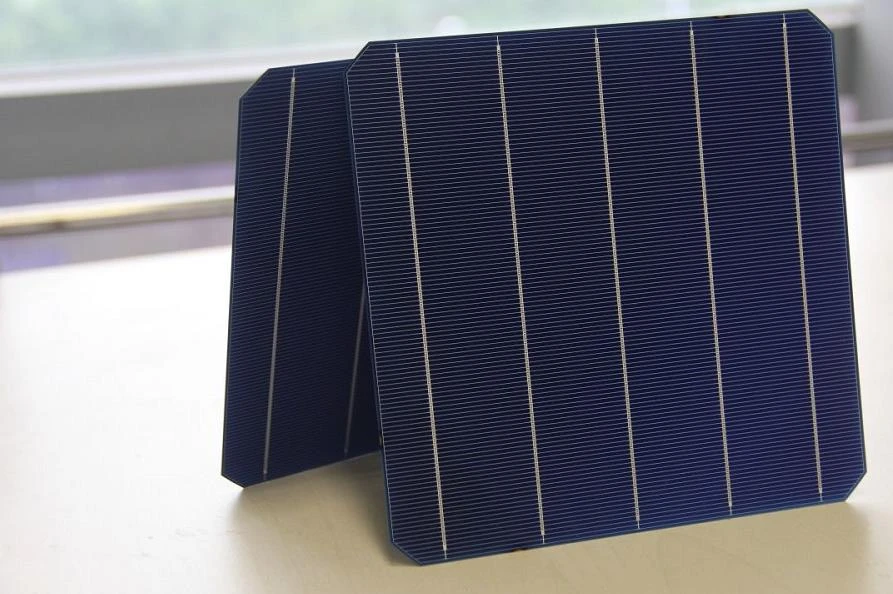

JA 610-635W N-Type Bifacial Double Glass Mono Module Solar Panel

The cost of factory solar panels, a pivotal topic in sustainable manufacturing, intersects diverse factors such as technological advancements, production efficiencies, and global economic shifts. Understanding these influences not only underscores the strategic decision-making in adopting solar energy but also aligns with corporate sustainability goals. Here's an insightful exploration of the cost dynamics surrounding factory solar panels, backed by real-world experiences, professional insight, authoritative data, and trustworthy analysis.

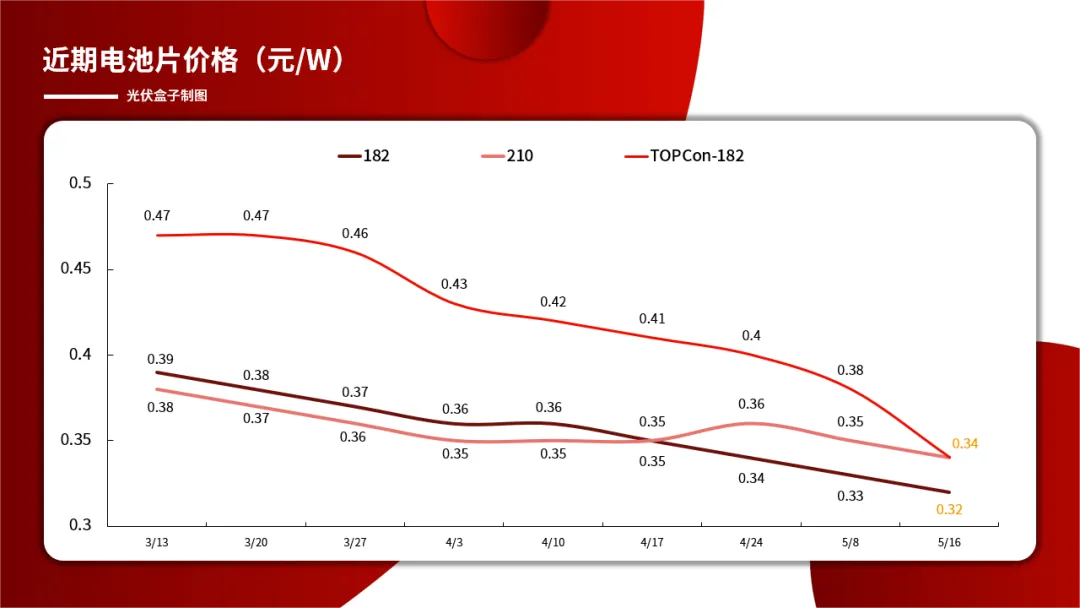

Energy savings achieved through solar energy adoption directly impact a factory's operational costs. Once installed, solar panels provide a virtually free energy source. This reduction in dependency on traditional energy suppliers allows factories to allocate financial resources elsewhere, fostering innovation and expansion opportunities. Moreover, the environmental benefits of solar panels are driving manufacturers to bear the initial costs for long-term gains. By reducing carbon emissions, solar energy attracts environmentally-conscious clients and partners, thereby enhancing a brand's image and consumer trust. Real-world case studies provide compelling evidence of the benefits associated with factory solar panel investments. Consider the example of a mid-sized manufacturing plant in the Midwest United States that installed solar panels covering its vast rooftops. The plant reported a 35% reduction in electricity costs within the first year, translating to annual savings in the six-figure range. The success of this initiative has not only improved the plant's environmental footprint but also increased its market competitiveness. The professional community acknowledges that the price trajectory of solar panels is downward. This trend is underpinned by continuous innovation, increased competition among manufacturers, and heightened awareness of renewable energy's importance. Companies that invest in solar technology today position themselves advantageously for future cost efficiencies and regulatory benefits. Authentic testimonials from industry leaders and renewable energy experts reinforce the perspective that investing in solar energy is a strategic long-term financial decision. These endorsements, coupled with empirical data and government-supported research, further solidify trust in the viability and sustainability of factory solar panels. In conclusion, the cost of factory solar panels, when evaluated beyond the upfront investment, is a multifaceted calculation that integrates technological advancements, economic considerations, regulatory incentives, and long-term strategic gains. As corporations seek to balance cost with sustainability objectives, the integration of solar panels in manufacturing holds the potential for substantial financial and environmental returns. This narrative not only captures the essence of investment in solar energy but also serves as a testament to the evolving landscape of sustainable manufacturing practices.

Energy savings achieved through solar energy adoption directly impact a factory's operational costs. Once installed, solar panels provide a virtually free energy source. This reduction in dependency on traditional energy suppliers allows factories to allocate financial resources elsewhere, fostering innovation and expansion opportunities. Moreover, the environmental benefits of solar panels are driving manufacturers to bear the initial costs for long-term gains. By reducing carbon emissions, solar energy attracts environmentally-conscious clients and partners, thereby enhancing a brand's image and consumer trust. Real-world case studies provide compelling evidence of the benefits associated with factory solar panel investments. Consider the example of a mid-sized manufacturing plant in the Midwest United States that installed solar panels covering its vast rooftops. The plant reported a 35% reduction in electricity costs within the first year, translating to annual savings in the six-figure range. The success of this initiative has not only improved the plant's environmental footprint but also increased its market competitiveness. The professional community acknowledges that the price trajectory of solar panels is downward. This trend is underpinned by continuous innovation, increased competition among manufacturers, and heightened awareness of renewable energy's importance. Companies that invest in solar technology today position themselves advantageously for future cost efficiencies and regulatory benefits. Authentic testimonials from industry leaders and renewable energy experts reinforce the perspective that investing in solar energy is a strategic long-term financial decision. These endorsements, coupled with empirical data and government-supported research, further solidify trust in the viability and sustainability of factory solar panels. In conclusion, the cost of factory solar panels, when evaluated beyond the upfront investment, is a multifaceted calculation that integrates technological advancements, economic considerations, regulatory incentives, and long-term strategic gains. As corporations seek to balance cost with sustainability objectives, the integration of solar panels in manufacturing holds the potential for substantial financial and environmental returns. This narrative not only captures the essence of investment in solar energy but also serves as a testament to the evolving landscape of sustainable manufacturing practices.

Latest news

-

Understanding the Advantages of Solar String Inverters for Your Energy SystemNewsApr.29,2025

-

Choosing the Right PV Inverter: A Comprehensive GuideNewsApr.29,2025

-

The Future of Solar Power: Exploring Bifacial Solar PanelsNewsApr.29,2025

-

The Complete Guide to Solar Panels: Efficiency, Cost, And InstallationNewsApr.29,2025

-

The Best Options for Efficiency and Cost-EffectivenessNewsApr.29,2025

-

Harnessing the Power of Off-Grid Solar Inverters for Energy IndependenceNewsApr.29,2025

Related PRODUCTS